Torch Applied Rolled Roofing

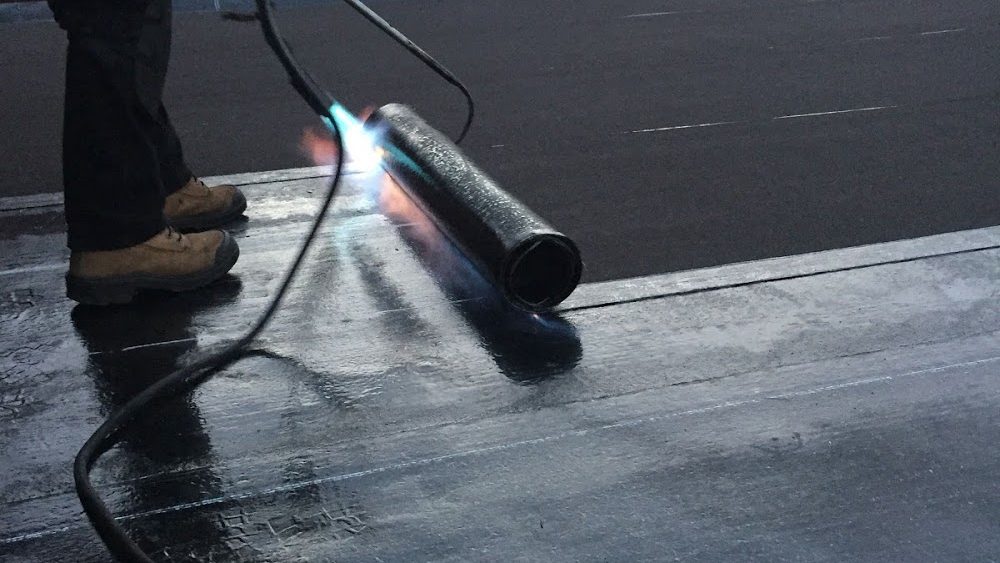

Move the torch slowly back and forth along the roll to heat it evenly.

Torch applied rolled roofing. Position the blue tip of the flame against the roll. Check the bitumen often as you unroll it. While it can last up to 20 years installing torch down roofing can be a dangerous process and as such tends to cost more than traditional roofing materials. Leatherback 1sq torch down roll roofing.

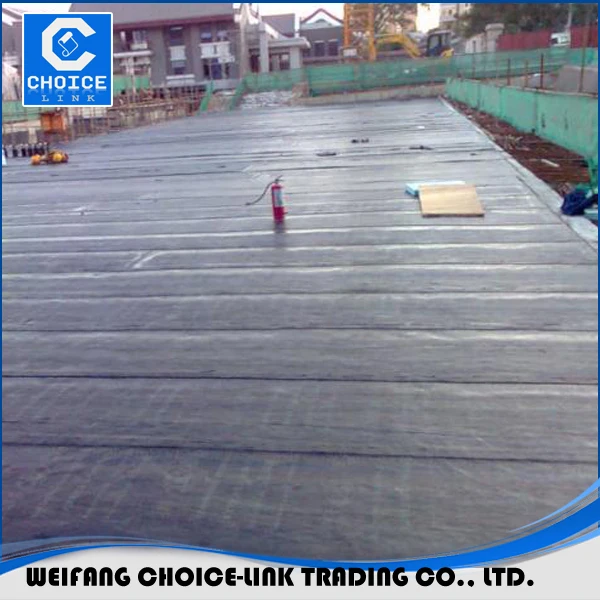

Your roofing contractor will unroll each sheet individually during the installation process two sheets for two layer three sheets for three layer. Each sheet of torch down roofing material consists of multiple membranes stacked and adhered together. Torch down roofing is a type of roofing material that has been designed for low angle or flat roofs. Torch down roofing is used on flat or low sloped roofs.

Cap sheet rolls. In this installation method sheets of modified bitumen are rolled out onto the roof and a roofing professional uses a hand held propane torch to heat the material and adhere it to the surface. Torch down roofing comes in the form of rolled sheets. Starting at just 55 each.

Starting at just 60 each. Torch down roofing sometimes referred to as torch on roofing is so named because it requires an open flame propane torch. Use your foot to push the melting roll towards the end of the roof. Ideal for any flat roof application.

Peel and seal 1sq roll roofing for flat roof applications. Atactic polypropylene app is heat torch applied modified bitumen membrane that provides a greater re cover system uv resistance and increased durability for roofs with high traffic movement. Ft sbs self adhering cap sheet roll for low slope roofing in black liberty sbs self adhering cap sheet is a durable liberty sbs self adhering cap sheet is a durable modified bitumen membrane designed and manufactured to meet industry and code requirements. As the name implies it involves the use of a blowtorch to melt a petroleum based substance called bitumen to create a waterproof seal with the roofing material.