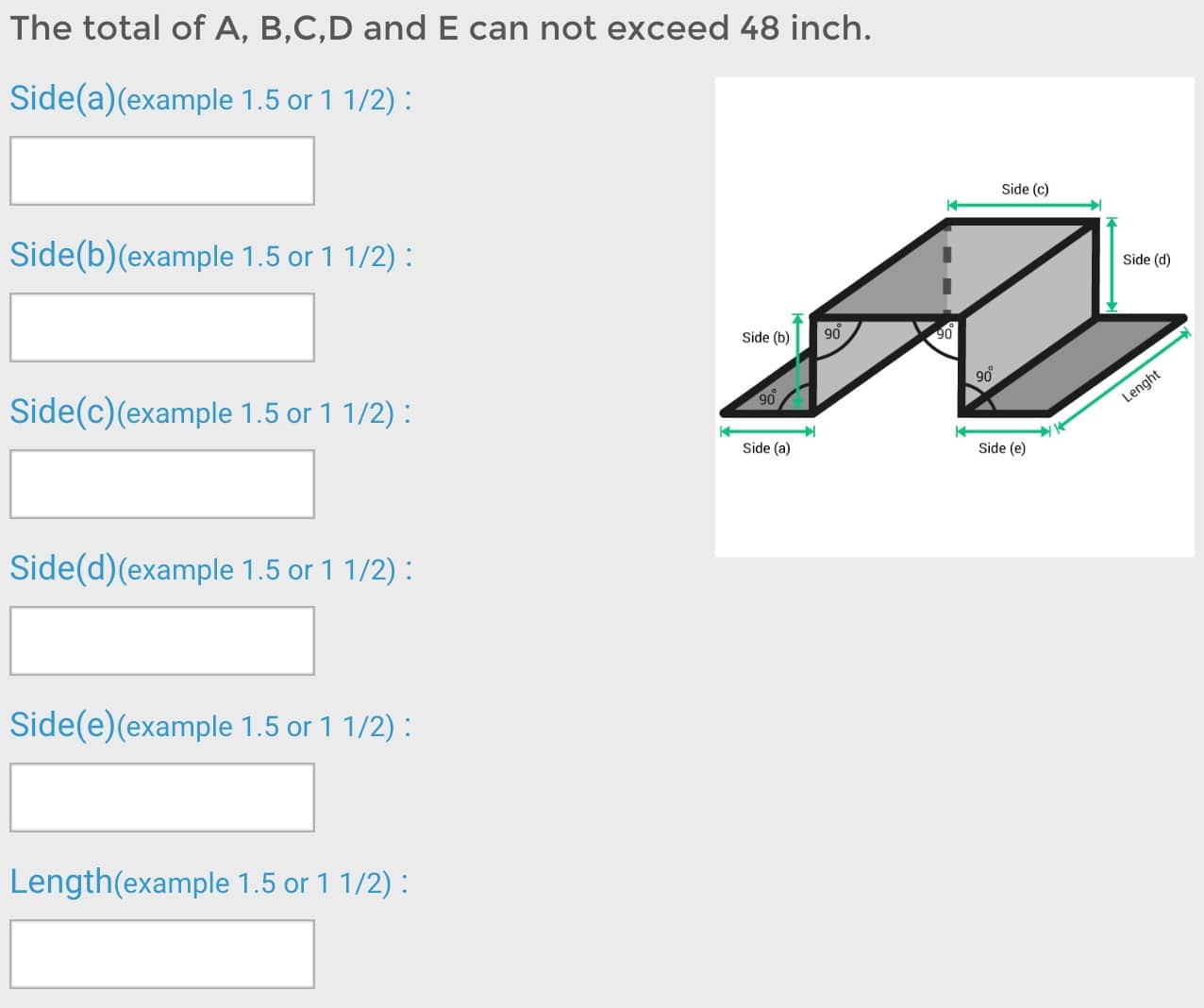

Tophat Sheet Metal Bend

Special processing method of z bending.

Tophat sheet metal bend. The inside bend radius should be equal to the thickness of the material that you re forming. 3 8 out of 5 stars 94. Learn how to bend sheet metal so you. Bend tech sm sheet metal software 3d for review.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. The force must exceed the material s yield strength to achieve a plastic deformation. Get it as soon as thu sep 17. 30 steel bending brake sheet metal bender tool.

Highfree 6 inch straight jaw sheet manual metal bending pliers sheet metal hand seamer metal pipe bender non slip pitted handles. Bending is one of the most common sheet metal fabrication operations. Bend tech sheet metal takes a practical approach to sheet metal design and is by far the most easy to use sheet metal design product. Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one.

The diagram shows one such mechanism. Solidworks tutorial sheet metal 2012 what. Using two acute angles to form z bending. This is done through the application of force on a workpiece.

How to bend sheet metal without a brake duration. If you re bending 0 020 thick material use a 0 020 radius. Geometry of tooling imposes a minimum bend dimension. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. Custom cut sheet metal in the form of a hat channel. An upper mould punch and a lower one the die and a sheet metal located between them. In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend.

3 4 out of 5 stars 4. 1 if there is a collision first bend 1 to form a large angle then bend 2 and then press 1. The sheet metal bending with v die or air bending probably the most common when the need is to reach corner till 90 it s realized with just two tools. Cosador recommended for you.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork. 2 if no collision as per general z bending processing method first bend 1 and then bend 2. Refer to the chart for values for folder as well as various press brake tooling combinations.