Thinning In Sheet Metal Forming

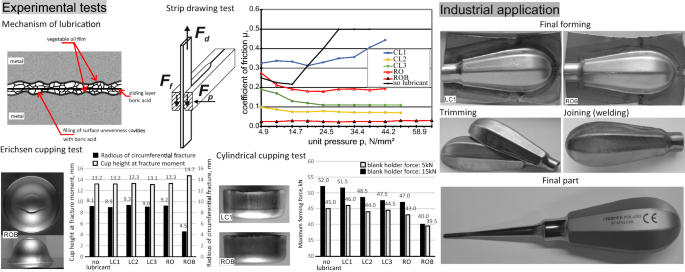

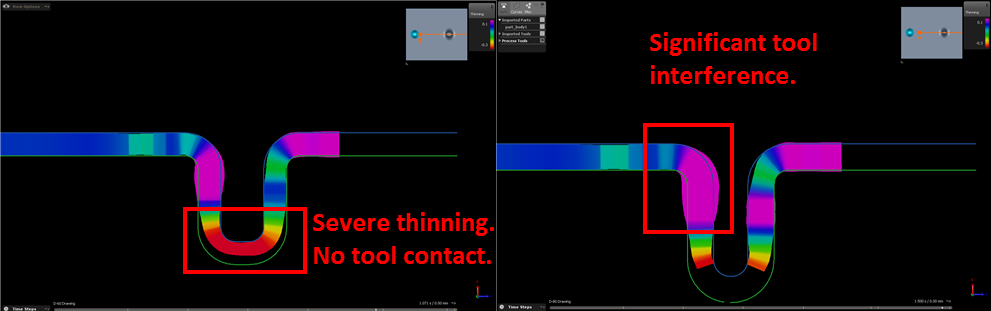

An excessive thickness reducing ratio of the deformation zone in single point incremental forming of the metal sheet process has an important influence on the forming limit.

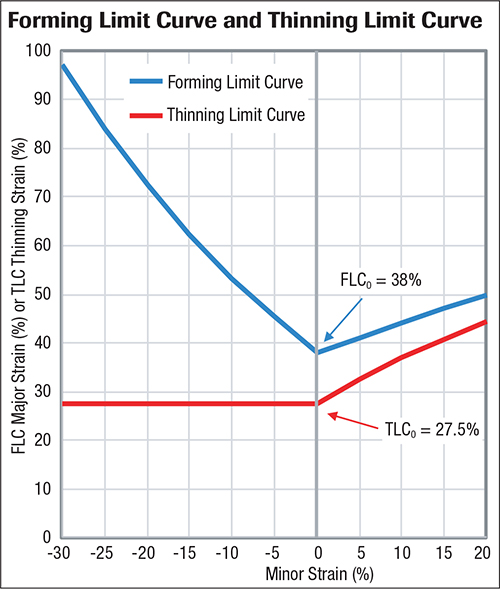

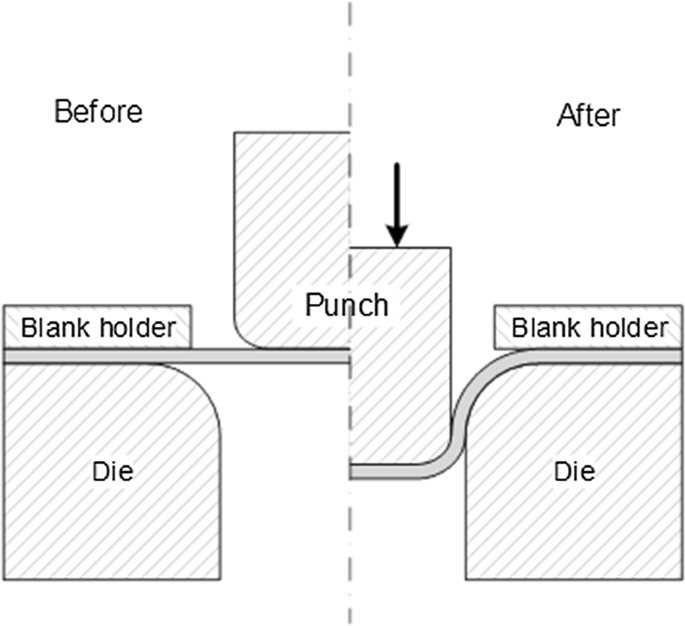

Thinning in sheet metal forming. The coils are formed. A real sheet will at some point crack during forming. The starting thickness of your sheet metal call that s and the formed thickness of your part at the location of interest call that f. Thickness to diameter ratio is a main factor used to quantify the geometry of a blank and can be calculated by t d b.

There are material tests e g. Sheet metal is available in flat pieces or coiled strips. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly.

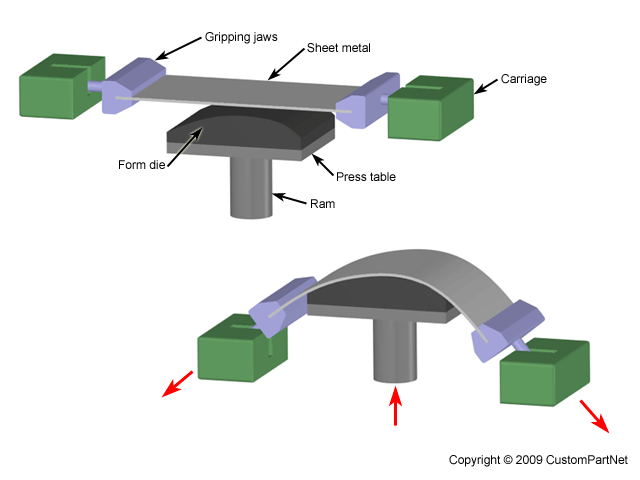

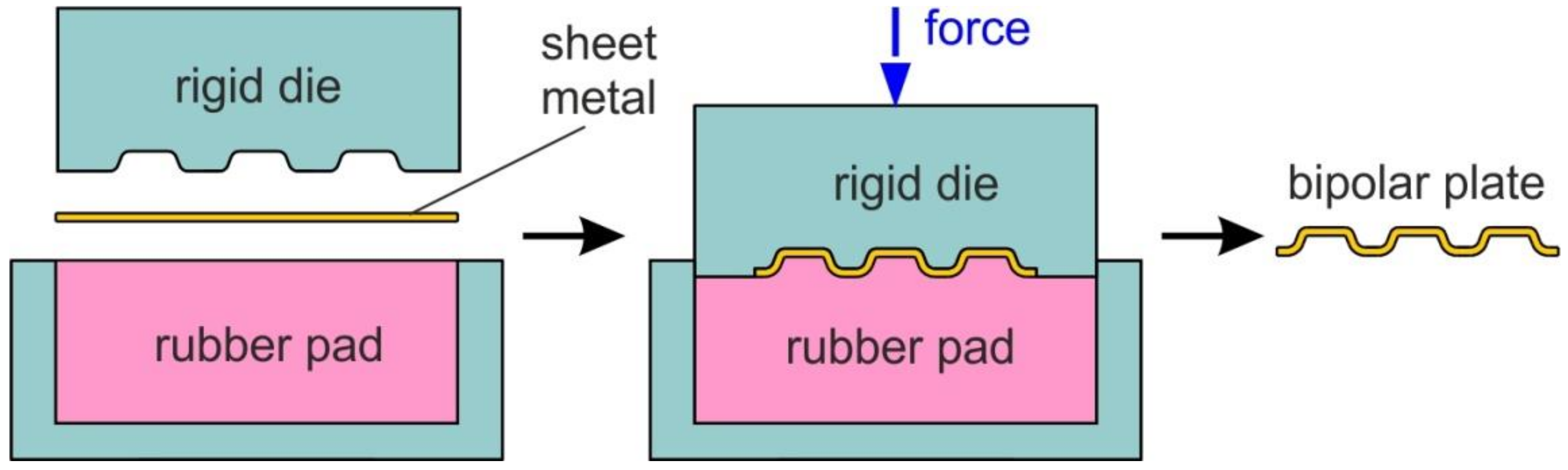

The more you flatten the material the larger the circle becomes and the thinner the cross section. A substantial fraction of all metals are produced as thin hot rolled strip or cold rolled sheet. In this study varying widths of low carbon steel sheets were punch stretched under laboratory conditions. Hydro forming cheap tooling no net thinning slow high formability material stretched into shape stretch forming very cheap tooling net thinning slow low formability super plastic forming cheap tooling net thinning expensive sheet metal slow very high formability technology a brief review forming speed 20.

The resulting strain state in the center of the specimen depends on its shape. If you have accurate measurements you can have confidence in your results. Thickness is represented by t and d b is the diameter of the blank. It is believed that a critical amount of thinning takes place in a sheet metal before failure.

This can also be visualized in the diagram. Sheet metal thickness is an important aspect of deep drawing process design. For noncircular sheet metal parts the maximum diameter is sometimes used. An easy example of this would be to take a ball of playdo modeling clay and flatten it out on a table.

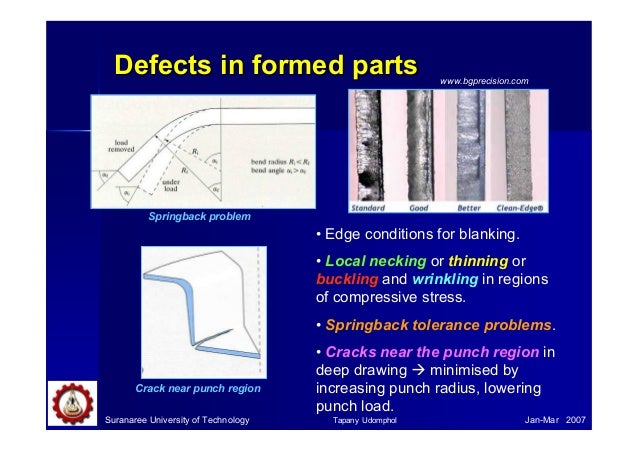

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm are considered plate steel or structural steel. Sheet metal is metal formed by an industrial process into thin flat pieces. Thinning in material is the result of stretching metal in the forming process. The nakajima test that have been developed specifically to represent the cracking behavior of sheet metal.

This is then formed in secondary processes into automobiles domestic appliances building products aircraft food and drink cans and a host of other familiar products. Countless everyday objects are fabricated from sheet metal. At this point you have two measurements. Prediction of the deformation zone thickness is an important approach to control the thinning ratio.