Thinning Defect In Sheet Metal

The edges are sharp the cutoffs are stiff and get in the way the snips bind or you just can t seem to negotiate the curve.

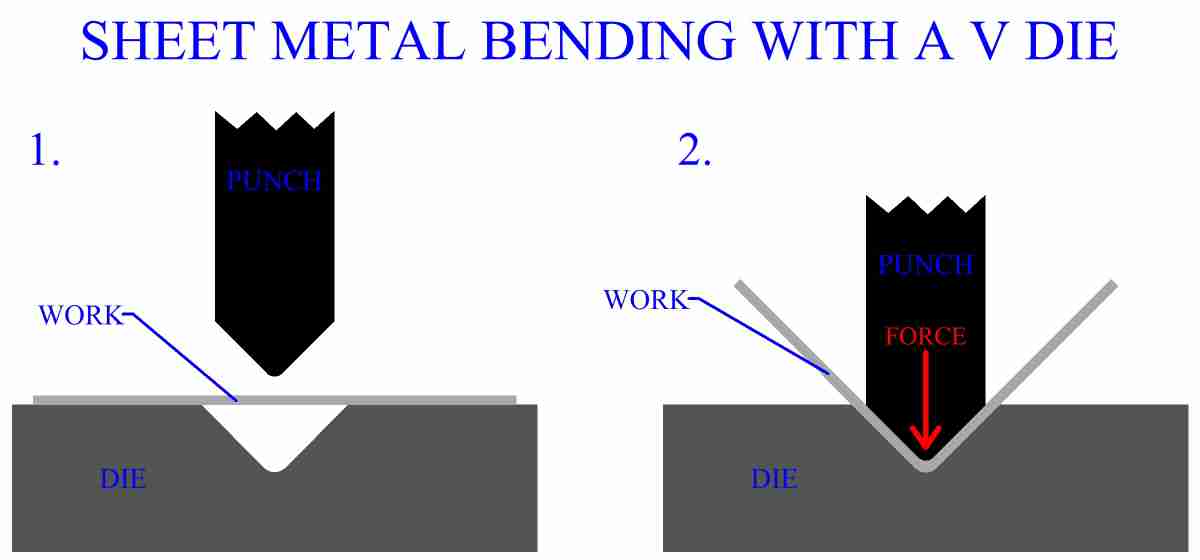

Thinning defect in sheet metal. If you think about sheet metal fabrication it costs from 700 to 1600 or even higher. All forming operations deform sheet material by exposing it to tension compression or both. If you would like to buy readymade sheet metal the cost would be way less. There are two reasons behind this defect.

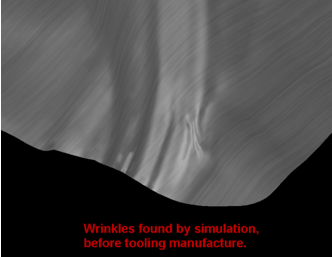

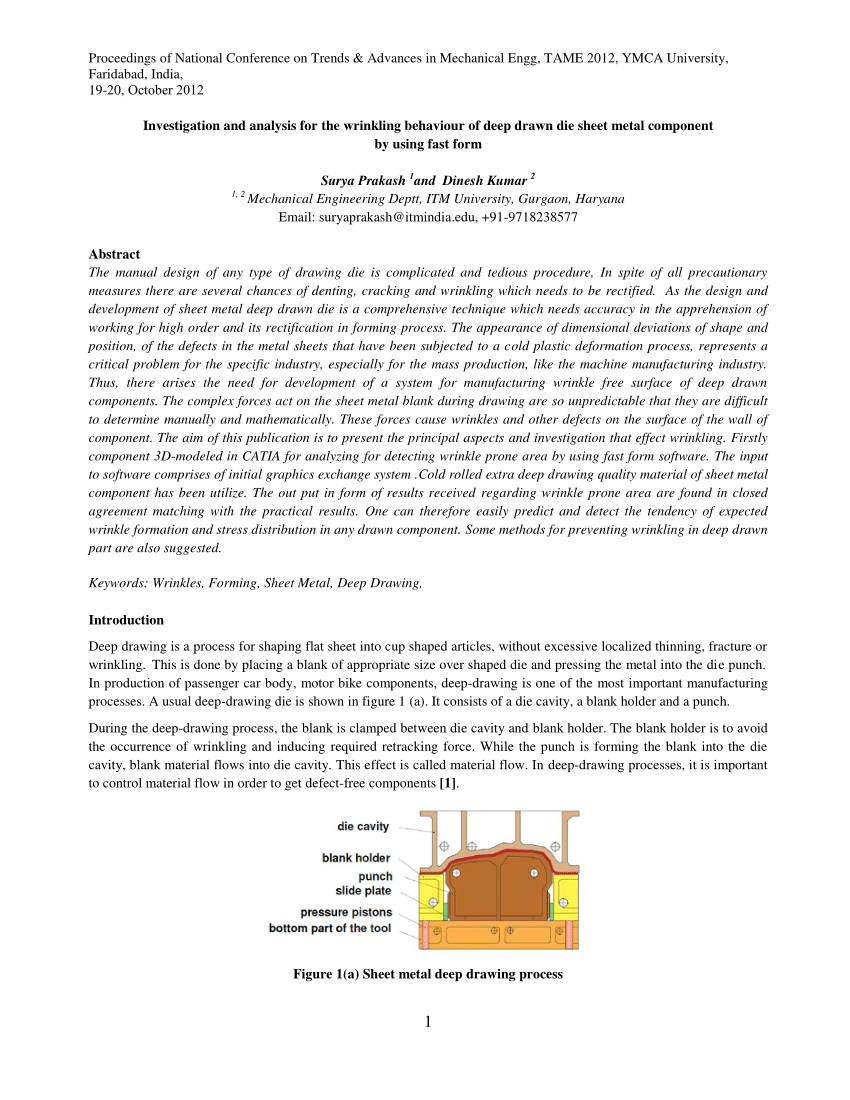

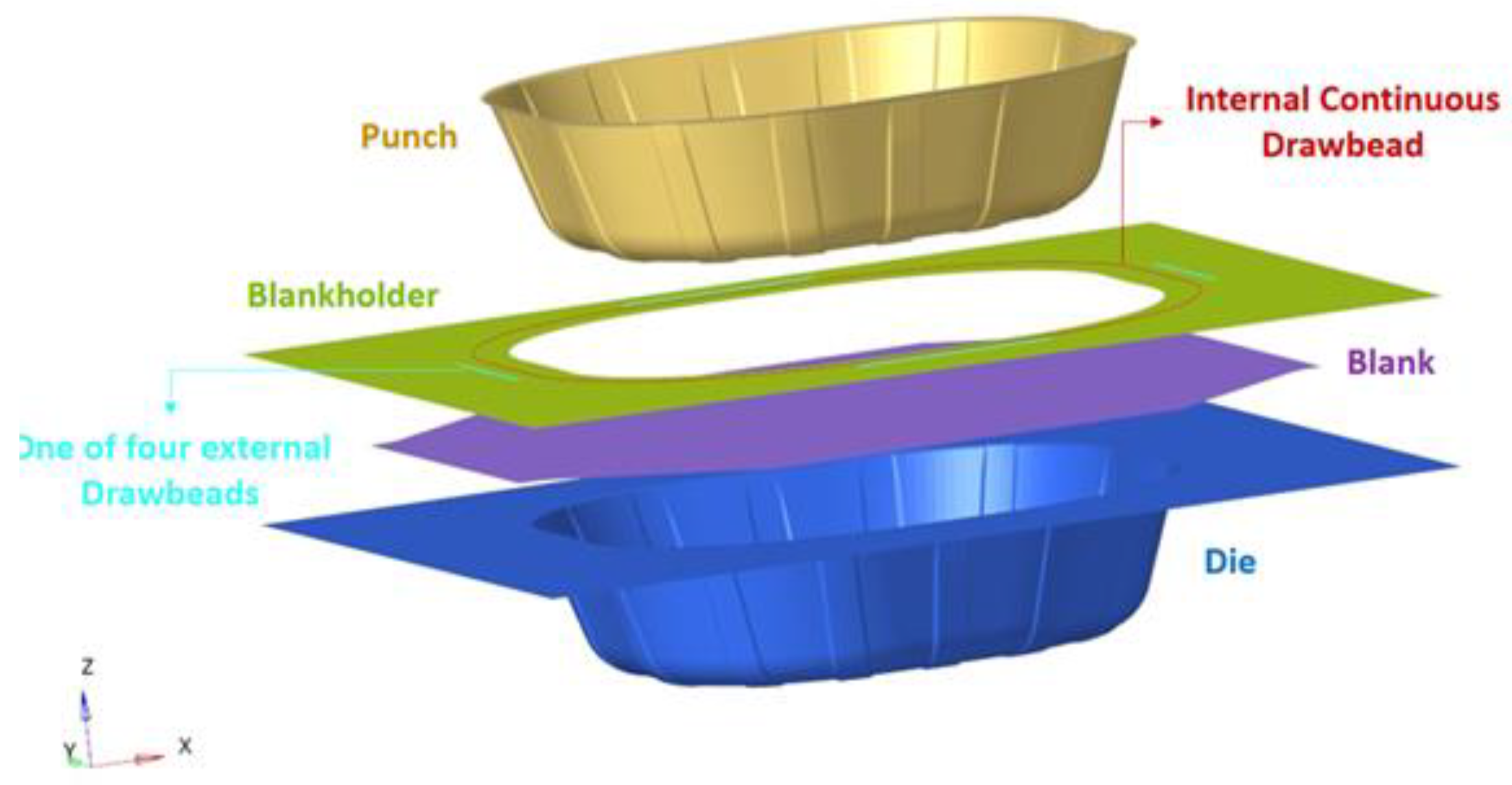

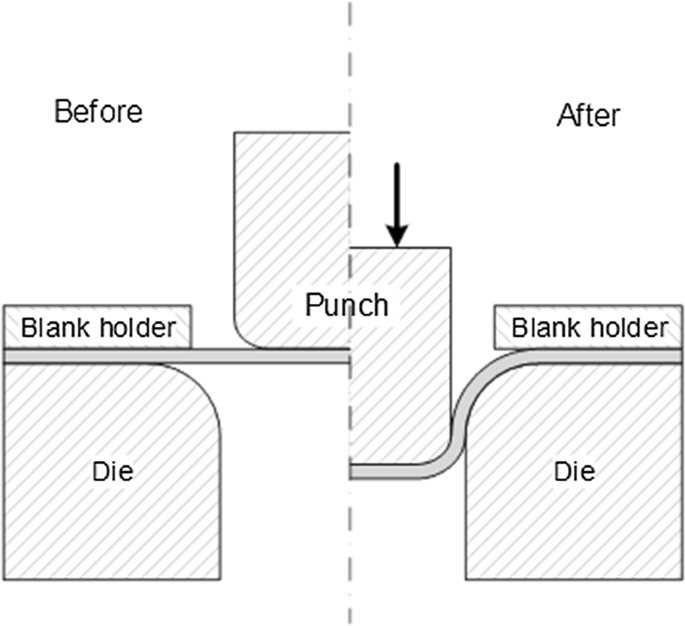

What does gauge mean in steel. One is the improper handling another one is the elasticity of sheet metal forming materials. One of the primary defects that occurs in deep drawing operations is the wrinkling of sheet metal material generally in the wall or flange of the part. Excessive thinning thickening of the sheet during forming.

Many researchers have attempted to design a controlled sheet metal forming process to achieve a desired product shape without defects. Any appreciable thinning is usually considered a defect as it reduces the strength of the material. But you don t have to be a tinsmith to cut sheet metal successfully. Incorrect blank shape and or size.

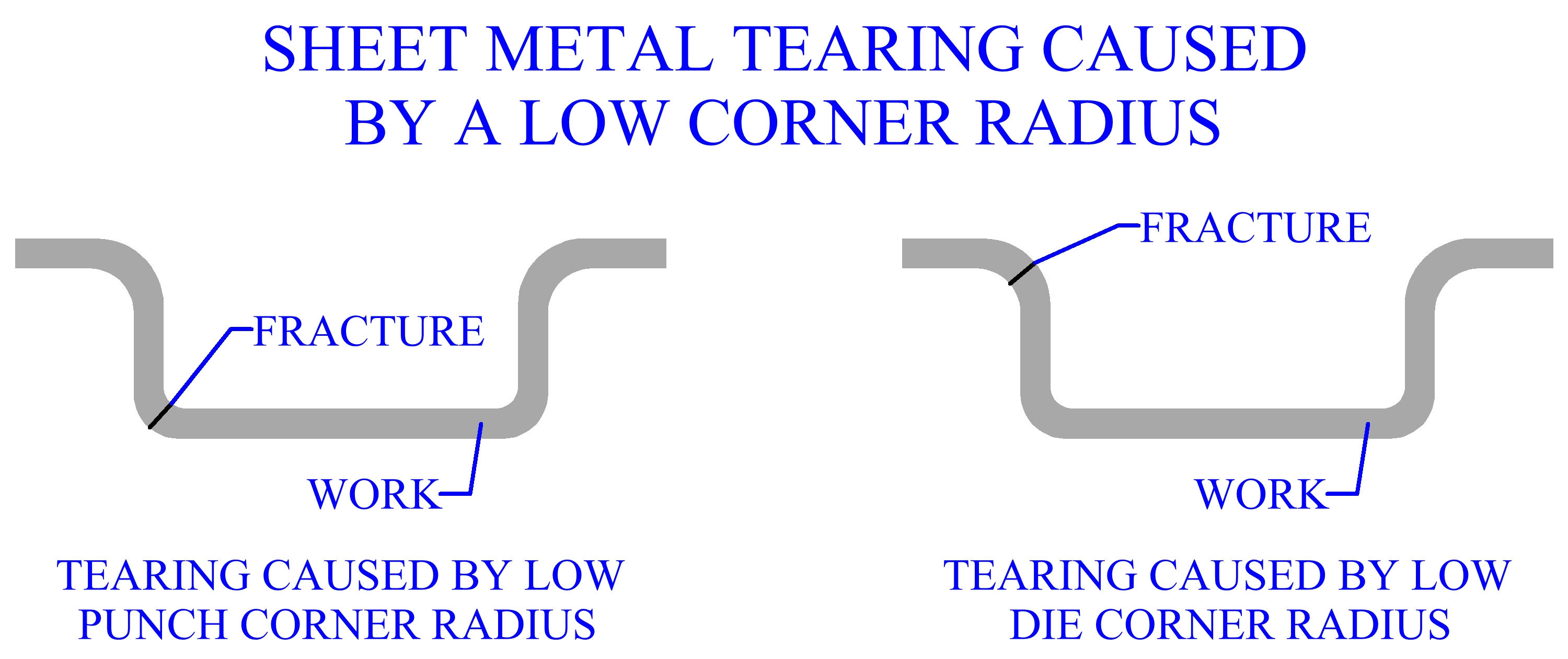

Causes of these are mostly too high or improper force distribution and material considerations. Splits a k a rips and tears splitting is what happens after necking. Tearing is one of the most common defects. An optimal blank holder force bhf profile is an efficient.

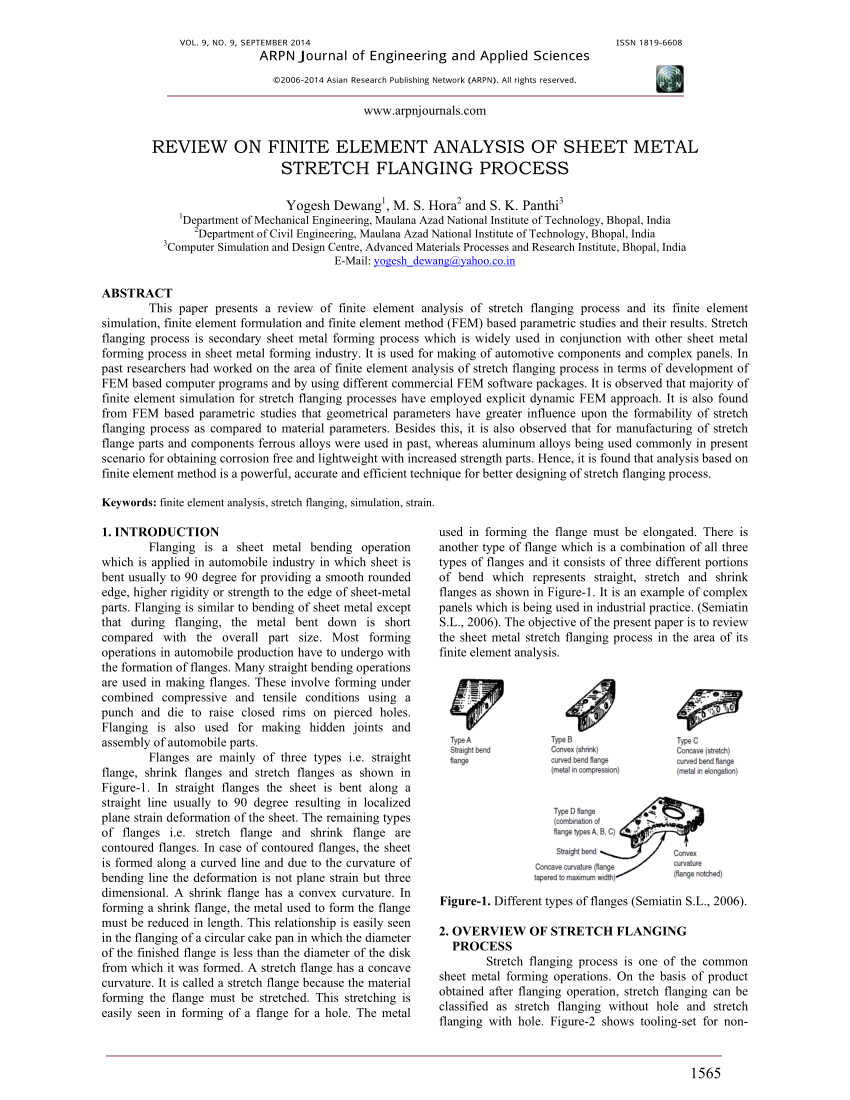

Examples of compression defects include. Springback or final part deviation from nominal incorrect process or number of forming tools. The wall thinning rate is an important indicator of formability that can reflect the thickness variation law and changing scope of the metal sheet. These problems are common for those of us who don t work with sheet metal every day.

The reason behind it is that welding positions are misaligned. For example for small projects like 4 4 or 4 8 would cost around 300. The metal being formed must have the ability to stretch and compress within given limits. The main reasons for the cracking are over stretching or stress concentration.

Wrinkles splits and springback are the three most common defects encountered during sheet metal stamping. How much does a sheet of the metal cost. Successful sheet metal forming relies heavily on the metal s mechanical properties. Excessive thinning in areas of the sheet metal is also an unwanted defect.

When a flat sheet is pushed in on itself the material needs somewhere to go. When the material can t thin any further it pulls apart creating a split or tear. When the wall thinning rate exceeds a certain range the part will have lower strength thereby greatly affecting the precision of the formed part. The wall thinning rate can be defined as follows.

Most part defects such as splits and wrinkles occur in forming operations.